Blog Details

- Home

- Blog Details

How EAM can help oil and gas companies

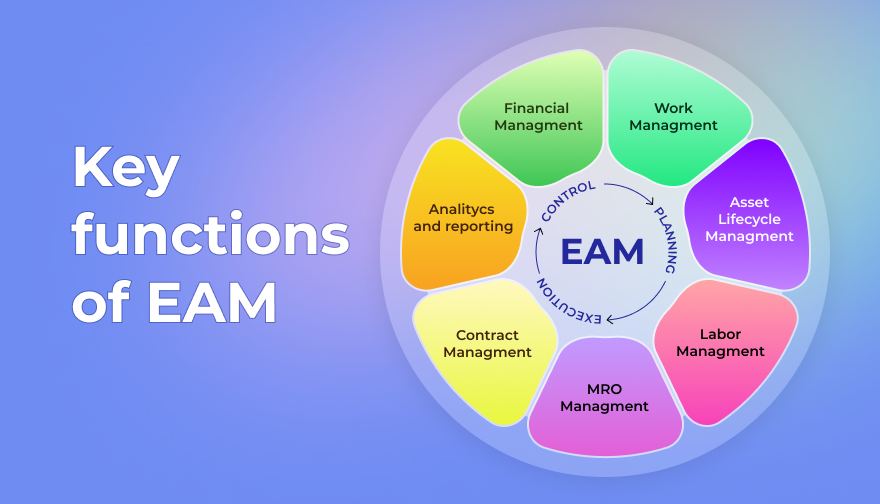

Enterprise asset management (EAM) can help companies more easily manage a complex array of assets, from drilling rigs and pipelines to refineries and storage facilities. The following are some of the most impactful ways oil and gas is embracing EAM as an asset management strategy:

- Asset lifecycle management: Oil and gas assets are intricate, costly and have lengthy lifecycles. EAM systems provide a centralized repository of all asset-related information, allowing teams to track the performance of each asset and make informed decisions about maintenance, upgrades and replacements.

- Predictive and preventive maintenance: The advent of IoT and AI technologies has transformed EAM systems into predictive maintenance tools. Sensors attached to assets can now gather asset data in real-time, and AI algorithms can analyze the data to predict potential equipment failures. EAM also plays an important role in preventive maintenance, which involves routine inspections and servicing to prevent breakdowns. Using EAM data to implement predictive and preventive maintenance programs helps oil and gas companies take a more proactive approach to asset maintenance, reducing unexpected downtime and minimizing costs associated with emergency repairs.

- Regulatory compliance: The oil and gas industry is subject to stringent regulatory requirements related to safety, environmental impact and asset integrity. EAM can help companies stay compliant by providing up-to-date documentation, tracking necessary inspections, ensuring that all equipment meets the required standards, and providing alerts for upcoming compliance-related activities. This not only helps businesses avoid regulatory penalties, but it also creates safer operations and improves public perception.

- Cost control and budgeting: EAM systems provide valuable insights into asset performance as it relates to maintenance costs. By analyzing asset data, companies can identify inefficiencies, uncover cost-saving opportunities and make more accurate budget forecasts.

- Inventory management: Managing an inventory of spare parts and materials is a significant challenge for oil and gas companies. EAM systems can provide around-the-clock visibility into inventory levels, allowing businesses to track part usage, automate reordering processes, prevent stockouts and overstocking, reduce carrying costs and ultimately ensure that parts are available when teams need them.

- Risk management: Because EAM offers a comprehensive view of all critical assets, it can be an invaluable tool for identifying potential risks, empowering companies to take preemptive steps to avoid accidents and operational disruptions.